Global adventure for ACM CRC PhD candidate leads to worldly insights for Australia’s composites manufacturing sector

ACM CRC PhD student, Alex Air, recently embarked on a 3-month trip to Europe to spend time at DLR, the German Aerospace Centre. For Alex, this amazing opportunity was a real eye-opener into how composites manufacturing is managed on the other side of the world...

The work Alex undertook while overseas will form an integral part of his PhD research, with outputs offering valuable insight for future projects between DLR and ACM CRC.

“Thanks to ACM CRC’s support, I was able to complete research work in partnership with the team at the DLR Institute of Structures and Design in Stuttgart, Germany, as well as being given the opportunity to visit their sister facility in Augsburg, and thermoplastic fibre placement equipment manufacturer AFPT,” said Alex.

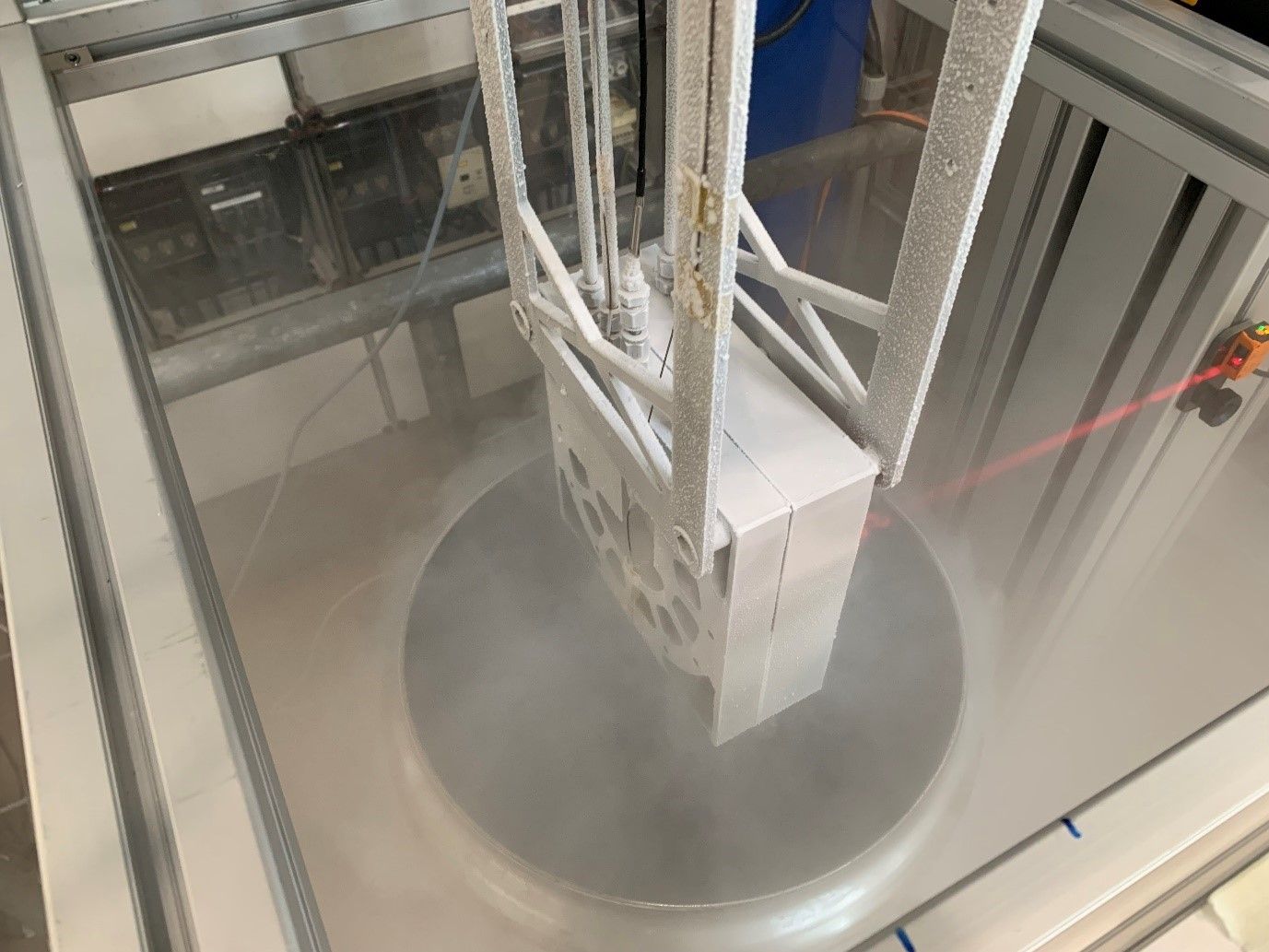

“My time at DLR focussed on conducting helium permeability measurements of carbon fibre samples produced using automated fibre placement at room and liquid nitrogen temperature. I also got to see how they perform their research and utilise similar equipment to what we have at UNSW, but in different ways – which was a great learning experience.

“I realise this all sounds very technical to the non-scientist, but to a researcher in composites manufacturing, it was truly very exciting!”

While in Europe, Alex also dropped into the University of Bologna, Ravenna, Italy, to present at the 27th International Conference on Composite Structures (ICCS27). Presenting as part of a special session, “Recent developments and challenges in design and manufacturing composite pressure vessels”, Alex focused on his work with colleagues Dr Ebrahim Oromiehie and Prof. Gangadhara Prusty in automated fibre placement manufacturing of composite pressure vessels.

Alex concluded his trip at the National Composites Centre in the UK, where he got to see their large format Electroimpact AFP/ATL cell, Coriolis C1 AFP cell and their ultra-high-rate deposition cell, custom developed with Loop Technology.

“This trip has been the highlight of my PhD experience. Conducting research in a new environment with different people was a fantastic way to broaden my perspectives and gain deeper technical and practical knowledge. And being able to share my own knowledge with a room full of composite manufacturing enthusiasts in Italy was just incredible.

“I would like to thank everyone who made this trip and the broad expansion of my education possible, especially Sebastian Nowotny, Head of Component Design and Manufacturing Technologies at DLR Stuttgart, for his time and investment into making my trip so valuable, and to ACM CRC, without whom this trip would not have happened.

“I look forward to applying my learnings to my PhD, and using the outputs to help advance the Australian composites manufacturing industry,” Alex concluded.