9 Questions with Sharine Bendulo, ACM CRC PhD Student

Our PhDs are playing a significant role within our program, and in the broader industry.

Here, we introduce you to Sharine Noelle Bendulo from one of ACM CRC’s university partners, Deakin University.

Sharine is a third-year Materials Engineering PhD candidate. She graduated with a BS and MS in Chemistry from the University of the Philippines Diliman, and has a deep passion for organic synthesis, materials chemistry and composite materials. Her ambition is to take on a research and development role after her PhD, contributing to automotive, aerospace or defence projects. Sharine’s current research interests include: vitrimers, advanced composites, high performance structural materials, and resin development.

Q1. Under which ACM CRC Research Program does your PhD Masters project sit?

My PhD project is under Research Program 1: High Performance Composite Materials.

Q2. What is the focus of your PhD Masters?

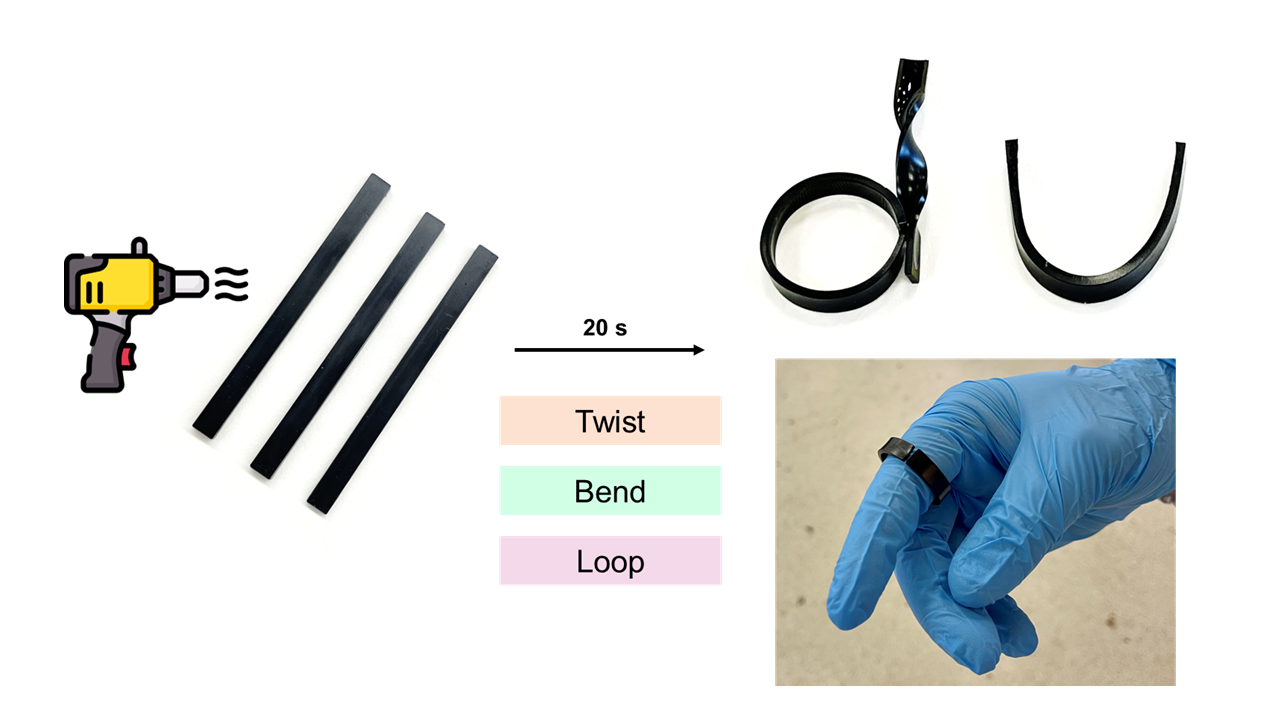

My research is focused on the development of reprocessable high-performance epoxy vitrimers based on dynamic imine bonds. The goal is to develop alternative matrix materials for high-performance carbon fibre composites that would enable composite repair, reshaping and welding even after hardening. This would also extend the life of crosslinked polymer networks, keep them in the circular economy of plastics, and impart properties that were previously only possible for thermoplastics.

Q3. When did you become interested in this field?

When I was in high school, my brother and I loved watching shows on the Discovery Channel and National Geographic on air crash investigations, mega builds, and how things are made. These shows often featured materials chemists who explained the causes of material failure, the design principles of high-strength structural materials, and the underlying science of manufacturing. It was through these shows that I developed a keen interest in the field and aspired to become a materials chemist.

Q4. What made you interested in it?

I was fascinated by the concept that molecules could be deliberately designed to achieve specific properties tailored for various applications. For instance, the assembly of polymer chains and how the interactions of functional groups on the chains directly influence the properties of polymers. This curiosity led me to join a polymer research lab during my undergraduate studies in chemistry, where I gained firsthand experience. This exposure introduced me to the diverse applications and significant potential of polymers and their composites, solidifying my interest in this field.

Q5. What do you hope to achieve through your PhD? What challenges are you hoping to solve?

Through my PhD research, I aim to address the challenges of circularity and the inherent limitations of thermosets and their carbon fibre composites. The excellent thermal stability and high mechanical strength of thermosets stem from their crosslinked network structure, but this also makes them difficult to reuse, repair, and recycle. My goal is to modify their molecular structure by incorporating dynamic bonds and transforming them to vitrimers to allow thermally activated material flow to overcome these challenges and integrate them into the circular economy of plastics. Additionally, unlike thermoplastics, which can be melted and reshaped upon heating, the crosslinked nature of thermosets prevents them from melting, hence limiting their processability and reprocessing. Existing epoxy-based composites must be transported and stored at low temperatures before shaping and curing, and once hardened, they cannot be reshaped or welded together. My goal is to address these challenges by developing modified thermosets, or vitrimers, with enhanced reshapability and weldability as well as high performance, thereby expanding their versatility and utility in various industrial applications.

Q6. What are your long-term goals/ambitions?

My long-term goal is to pursue a research and development position in the industry or within a research institution after completing my PhD. I aim to contribute to the development of innovative materials that address key challenges in the polymer and composites industries. Specifically, I aspire to work on solutions that can enhance the performance and sustainability of materials used in sectors such as automotive, defence, and aerospace, ultimately contributing to technological advancements and societal benefits.

Q7. What’s the best thing about being an ACM CRC PhD student?

Being able to meet and learn from people in the composites industry would be the highlight for me.

Q8. What one piece of advice would you give to people thinking of undertaking a PhD in the composites manufacturing area?

I would say to learn as much as possible about polymer matrices and fibres. A deep understanding of their properties, interactions, and how they influence the performance of the final product are invaluable.

Q9. Tell us something about you that would surprise/impress people.

Prior to pursuing my PhD degree, I also conducted research on protein-protein interactions and proteomics as well as the development of electrochemical sensors and magnetic nanoparticles for peptide fractionation. These experiences broadened my knowledge and exposed me to laboratory techniques and instrumentation vastly different from those used in polymer and composites manufacturing. This exposure has enhanced my multidisciplinary approach to research and fostered a strong sense of adaptability. Additionally, my work in protein research deepened my appreciation for how organic chemistry and synthesis can be effectively applied to fields like molecular biology, which may initially seem unrelated.

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.

Australian Composites Manufacturing

Cooperative Research Centre

(ACM CRC)

Level 1, Greenhouse

180 George Street

SYDNEY NSW 2000

SITE LINKS

FOLLOW US

Acknowledgement of Country

In the spirit of reconciliation, ACM CRC

acknowledges the Traditional Custodians

of country throughout Australia and

their connections to land, sea and community.

We pay our respect to their Elders past

and present and extend that respect

to all Aboriginal and Torres Strait Islander

peoples today.

STAY INFORMED

Australian Composites Manufacturing CRC

Website by Rogue Web Design