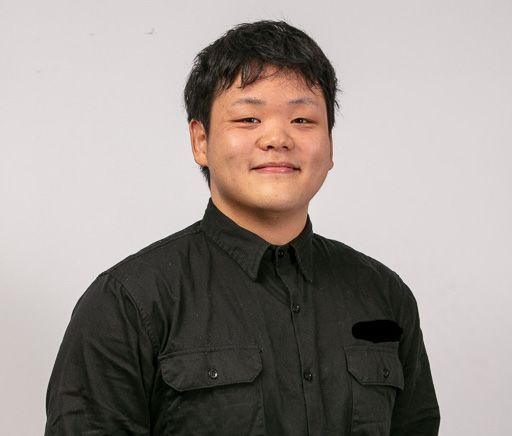

9 questions with Dex Chang, ACM CRC PhD Student

Our PhDs are playing a significant role within our program, and in the broader industry.

Here, we introduce you to Dex Chang, from one of ACM CRC’s university partners, The University of Sydney.

1. Under which ACM CRC Research Program does your PhD project sit?

I’m working on design optimisation with circular design 4.0: Artificial Intelligence based quality control manufacturing health monitoring reuse and recycling of composite connections, which falls under ACM CRC Research Program 1 (Composite Materials) and Research Program 4 (Design, integration).

2. What is the focus of your PhD?

My PhD program focuses on using numerical design with circular design 4.0 techniques to optimise the connection design in steel-timber composite structures. It mainly focuses on the innovative connection design between the timber slab and steel beams.

The industry has widely adopted traditional mechanical fasteners as the solution. However, recent research on novel connection designs, such as concrete grouted mechanical fixings, mechanical connections with epoxy, inclined fixings with nailed washers and new mechanical fasteners with nail plate reinforcement, suggests that the conventional connection has lower stiffness and load-bearing capacity, which means it's no longer the best option when considering sustainability and reusability.

Also, when considering the design with environmentally friendly techniques, which requires a high utilisation rate of the raw materials and reusability of the existing building element, a more sustainable modular steel and timber composite connection is becoming popular. My research is focusing on achieving a circular design 4.0 design tool for such new connection design to assist the industry.

3. When did you become interested in this field?

After discussing the topic with my supervisors, I learned that it requires us to incorporate timber elements with steel. I was really interested in and did well in steel and concrete composite structures when I was studying for my master's degree. Composite design is challenging but interesting since it can have a huge impact on the construction of new buildings.

4. What made you interested in it?

The use of circular design 4.0 has become quite popular in the construction industry in recent years. This project can be good practice for implementing circular design 4.0 and AI techniques to achieve an optimised design outcome and serve the demanding industry on the newly proposed timber and steel composite structures. Such connection with the idea of modularity and reusability will have huge potential in the construction of residential buildings, save the overall cost of the construction project and protect the environment.

5. What do you hope to achieve through your PhD? What challenges are you hoping to solve?

I hope to achieve a design tool to assist industrial engineers in the design of the relative connection with AI and machine-powered analysis. The expected challenges that I hope to overcome are: (1) Develop a new idea for connection design that meets sustainability requirements while minimising material use and installation difficulty; (2) To implement Circular Design 4.0 with this connection design process, and determine what parameters or evaluation criteria we should set to determine whether the outcome satisfies our goals; and (3) Regarding the AI-based connection design process, overcome the difficulty of bridging the image processing techniques with FEA analysis techniques.

6. What are your long-term goals/ambitions?

I'll try to accomplish the current project and then potentially further my study in the timber composite structure and modular element design for construction.

7. What’s the best thing about being an ACM CRC PhD student?

Rather than another normal PhD project, we have specialised industrial partners that can provide valuable suggestions on the connection design and well-collected industry data, and help us to examine the feasibility of the outcome in real-world construction projects. Also, with the powerful community of our association, we students can have a better understanding of the connection between research and industrial needs to facilitate our design to stay on track with the industry.

8. What one piece of advice would you give to people thinking of undertaking a PhD in the composites manufacturing area?

Finding the right track for composite structure and a novel topic is quite challenging. By reading articles from different realms of composite structure, researchers can get some inspiration from, for example, concrete composite and other new materials for construction.

9. Tell us something about you that would surprise/impress people?

My previous study focused on the animation and digital simulation of the construction process with Revit and Unreal Engine, and to optimise the simulation to achieve a smoother and more realistic viewer experience, and lower the hardware requirement using the LOD techniques powered by Unreal engine.

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.

Australian Composites Manufacturing

Cooperative Research Centre

(ACM CRC)

Level 1, Greenhouse

180 George Street

SYDNEY NSW 2000

SITE LINKS

FOLLOW US

Acknowledgement of Country

In the spirit of reconciliation, ACM CRC

acknowledges the Traditional Custodians

of country throughout Australia and

their connections to land, sea and community.

We pay our respect to their Elders past

and present and extend that respect

to all Aboriginal and Torres Strait Islander

peoples today.

STAY INFORMED

Australian Composites Manufacturing CRC

Website by Rogue Web Design