10 Questions with Sina Mansourdehghan

Our PhDs are playing a significant role within our program, and in the broader industry.

Here, we introduce you to Sina Mansourdehghan from one of ACM CRC’s university partners, University of Western Australia (UWA).

He’s a civil engineer specialising in structural engineering and has a background and keen interest in data science. Sina is focused on integrating computer science into structural analysis and monitoring.

Q1. Under which ACM CRC Research Program does your PhD project sit?

My PhD project is under RP4 Design and Integration.

Q2. What is the focus of your PhD?

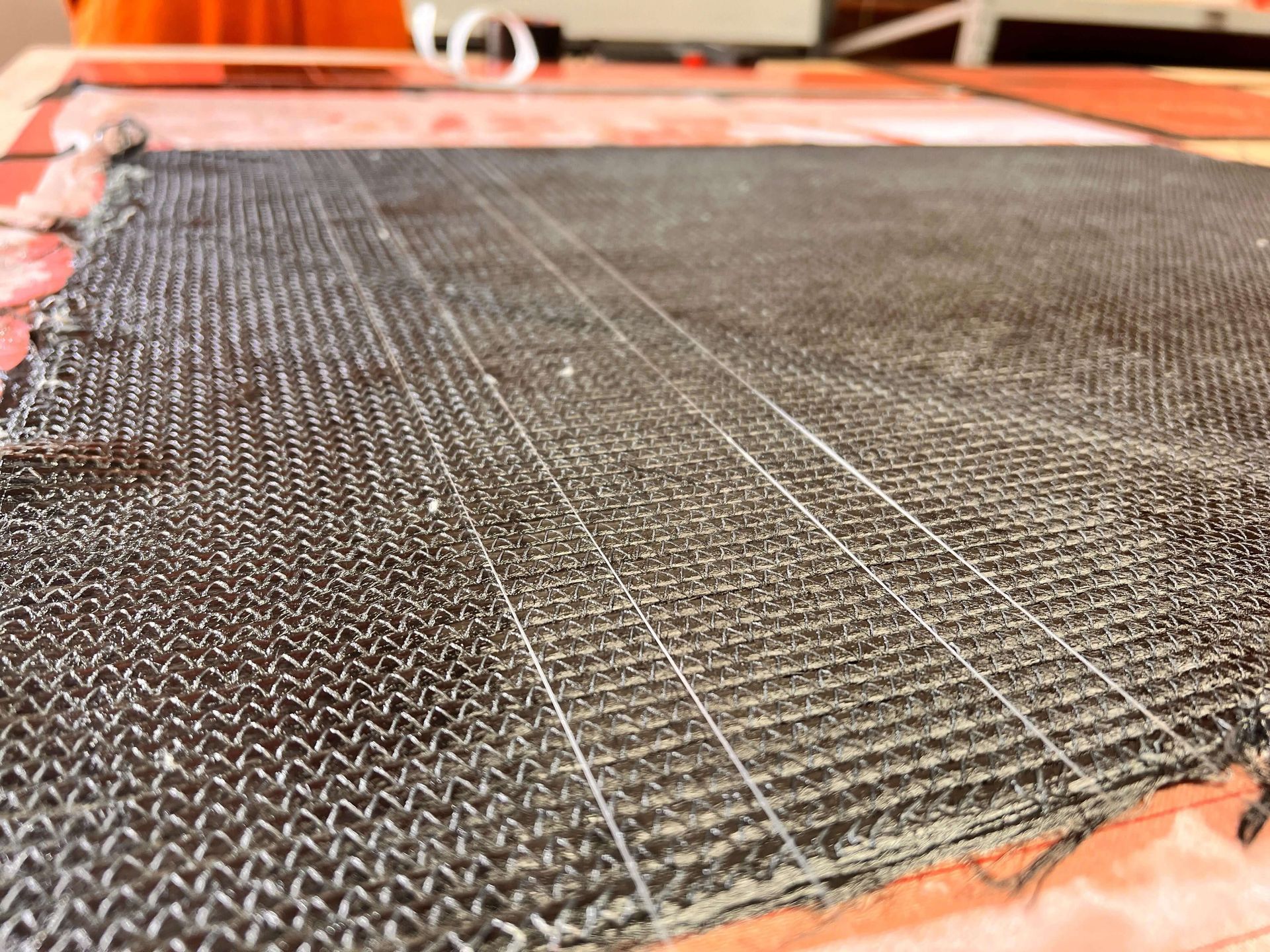

My PhD research focuses on the health monitoring of steel-composite bondlines. Specifically, I am working on developing Machine Learning (ML) approaches to detect and localise bondline damage using data from optical fibre sensors. To this end, I am designing and conducting experiments to gather data from both healthy and damaged structures to establish and validate my ML models. Ultimately, as a case study, my goal is to develop a monitoring system that includes optimised sensor arrangement and a data interpretation algorithm for tubular joint monitoring.

Q3. When did you become interested in this field?

During my MSc, my interest in this field began when I was working on structural health monitoring (SHM) of concrete structures using image data. This experience made me curious about applying ML-based methods to different types of sensor data. SHM has always motivated me, especially considering its potential for preventing future structural damage. Additionally, the challenge of adapting advanced ML models specifically for structural engineering applications is for me.

Q4. What made you interested in it?

Firstly, the necessity of developing a proper SHM system for regions with high seismicity for both onshore and offshore structures motivated me to work in the field of SHM to prevent future disasters. Moreover, using advanced ML methods in SHM further motivated me to deepen my knowledge and skills. Now, I’m excited to apply computer science techniques specifically to composite monitoring in my research.

Q5. What do you hope to achieve through your PhD? What challenges are you hoping to solve?

Through my PhD, I aim to develop a reliable health monitoring system for steel-composite structures that not only enhances the safety and durability of onshore and offshore structures, but also plays a role in preventing future disasters by identifying issues before they escalate. I hope to address challenges in sensor placement, data interpretation, and damage localisation in complex structures like tubular joints.

Q6. What are your long-term goals/ambitions?

I hope to make SHM systems more accessible and reliable, helping engineers predict and prevent structural failures, and contributing to safer, more resilient infrastructure worldwide.

Q7. What’s the best thing about being an ACM CRC PhD student?

The best part of being an ACM CRC PhD student is the strong support system and the sense of community.

Q8. What one piece of advice would you give to people thinking of undertaking a PhD in the composites manufacturing area?

Before starting a PhD, first, make sure you’re interested in research. If you have that drive, the composite manufacturing area is a growing field where you can make meaningful and impactful contributions.

Q9. Tell us something about you that would surprise/impress people.

I’m afraid I might not have something that would surprise you :) However, my passion for mathematics and engineering is closely tied to my deep interest in music and philosophy. I love discovering the connections and similarities between these fields, and I’m always interested in learning more about them.

Q10. Anything to add?

Thanks for your time! I’m happy to be a part of this community.

Interested to know more?

Visit our Education and Training page to learn more on our HDR Program, and how it’s helping to achieve industry transformation.